|

|

|

| |

|

|

|

The 3rd generation of MiniCore® reveals itself even simpler to use, more functional with an increased traceability. Discover now the new MiniCore® 3 and ask for a demonstration ! |

|

|

| |

| Expertise |

| |

| Now a World recognized Tissue Array expert, ALPHELYS have been designing for almost 10 years truely innovative Tissue Array dedicated solutions within a fully integrated approach of Tissue Array Platform. Years of experience cumulated with our customers and users have allowed us to design solutions which are really answering to problems arising in the use of the Tissue Array technique. |

| |

| Performance et productivity |

| |

|

|

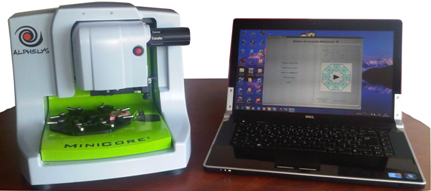

First installed in June 2008, the Tissue Arrayer MiniCore® brings in its 3rd generation even more functionalities, improvements for more simplicity of use, more traceability and productivity. Construction of tissue arrays is well known to be a tedious task, extremely time consuming for Pathology department staffs.

MiniCore® 3 allows building tissue arrays of 400 cores/100 patients in less than half a day while maintaining a high quality. |

The carrousel of the MiniCore® 3 can hold up to 7 donor blocks simultaneously or a combination of 6 donor blocks and 2 recipient blocks as a typical example to build 2 copies of the same tissue array at the same time for a very significant time saving.

|

|

| |

|

|

Specific accessories are proposed to allow for the process of large donor blocks (here on left) and of donor blocks on ring cassette (here on right). |

|

| |

|

|

| Ergonomics |

| |

|

|

Constructing a tissue array on a manual tissue arrayer or a tissue arrayer with limited automation requires sustained attention in an uncomfortable working position for many hours.

MiniCore® 3 ergonomics has been particularly studied for a comfortable and easy working position. MiniCore® 3 automatically manages positioning above recipient and donor blocks as well as depth of coring in both blocks to guarantee best histological match between all cores. |

MiniCore® Control Station software interface displays all of the tissue array data in real time. In case of difficulties with a particular donor block, operator can easily swap it with another donor block and continue the tissue array without quality loss.

|

|

| |

| Selection of the coring coordinates in the donor blocks is easily and quickly achieved directly at the image of the donor block displayed at the screen, superimposed with its matching H&E control slide. |

| |

|

| |

|

| |

| The tissue array can be achieved in one or multiple times upon operator’s agenda. MiniCore® 3 records all data allowing for quickly resuming the uncompleted tissue array. As recipient blocks can be removed any time from the unit, MiniCore® 3 can thus be used in parallel by multiple operators for different projects. |

| |

| Quality and traceability |

| |

|

MiniCore® 3 guarantees achievement of high quality tissue arrays whatever the size of the punch you have chosen from 0.6 mm to 2.0 mm, or quality of the donor blocks. The image of the donor core transferred in the recipient block is automatically displayed at the screen for operator validation. Operator can then react in real time in case of difficulty to collect the donor core and decide whether to try again or change the donor block if required to allow for the tissue array to be completed without specimens missing or damaging the specimens. |

| |

|

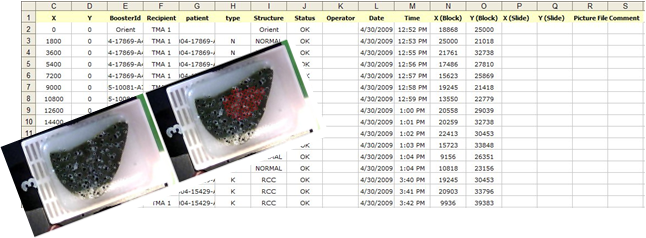

MiniCore® 3 guarantees a complete traceability from tissue array design to tissue array interpretation through construction. MiniCore® 3 captures automatically images of the donor blocks with their ID and records all operations into an Excel spreadsheet which compiles design and construction data as well as any comment entered by the operator.

MiniCore® 3 includes also an audit trail which records each and every step and errors into a log file. MiniCore® 3 is a true laboratory instrument complying with highest quality standards for Tissue array experts. |

| |

|

| Donor block image is captured before and after coring, image is overlaid with positions of each collected core. Actual cores coordinates in the donor block are saved in the Excel spreadsheet. |

| |

|

| |

| Flexibility |

| |

|

MiniCore® 3 is delivered with its steering computer installed with MiniCore® Control Station and TMADesigner® 2 Tissue Array Design Software. TMADesigner® 2 imports the list of specimens IDs from an excel spreadsheet. Settings as punch size, distance between spot, grid size, tissue type (normal, tumoral…), number of replicates per tissue type and per donor, number of tissue array copies, construction sequence (sorted or randomized) can be user adjusted upon needs.

Clinical items of interest can also be imported together with specimens IDs and will as a consequence be incorporated into the tissue array project Excel file.

Designing a new tissue array project does not required more than a minute to complete.

TMADesigner® produces a set of files that will be used by MiniCore® 3 to automate the construction of the tissue array. |

| |

| A complete solution |

| |

|

| |

Construction is only one of the steps of a tissue array project. Interpretation of the tissue array slide remains a tedious task to achieve and source of many errors.

This is why ALPHELYS propose a complete and integrated solution for tissue array as a Tissue Array Platform in which MiniCore® 3 is only a part of it.

ALPHELYS have developed a slide scanning microscope, GoodSpeed®, and more importantly a software totally dedicated to tissue array archiving, interpretation and analysis, Spot Browser® 3. First installed in 2002 in its first generation, Spot Browser® 3 is one of the most used tissue array specialized software in the World with numerous references in famous literature.

Spot Browser® 3 and MiniCore® 3 have been designed to perfectly communicate to guarantee perfect traceability. Spot Browser® 3 brings advanced functionalities including an automated matching between spot image and specimen ID thanks to the links with the tissue array file generated by MiniCore® 3. Read more aboutGoodSpeed® and Spot Browser® 3. |

| |

| Patented unique technology |

| |

|

MiniCore® design is based on an innovative punching mechanism employing the technology of coaxial punches where donor punch, recipient punch and stylet are concentric. This approach simplifies automation and eliminates the risk for misalignment between punches. ALPHELYS’ coaxial punches design is protected by a patent issued, amongst many countries, in Europe and in the USA. |

| |

Upgrading to MiniCore® 3 |

| |

| Users of MiniCore® 1 and 2, you can easily upgrade your equipment towards MiniCore® 3 to gain in performance, ease of use and traceability for a reasonable budget. Do not hesitate to ask for a quote. |

| |

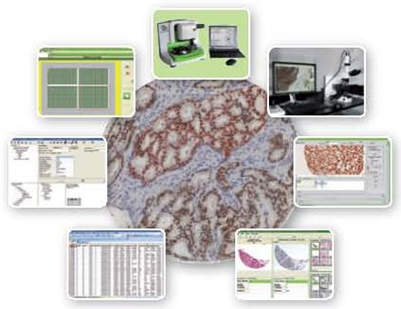

| The Tissue Array Platform |

| |

| The Tissue Array Platform is a unique solution fully dedicated to tissue array. It provides a complete and integrated solution for rapidly and efficiently achieving tissue arrays based research projects, from tissue specimens’ identification, to tissue array data processing through design, construction, slide scanning and image analysis. The Tissue Array Platform guarantees complete tracking and efficient data management while reducing human resources needs. |

| |

|

|

|

ALPHELYS,

Ferme des Ebisoires, Impasse Paul Langevin, 78370 Plaisir - France

Tel +33 (0)1 30 07 52 95 - Fax +33 (0)1 30 07 51 56 - eMail

info@alphelys.com

Copyright © 2001/2011 ALPHELYS, all rights reserved.

|

|

|

|

|